Features of super dry

SUPER DRY is produced with 43 years’ technology by Toyo Living, the first company established in Japan in 1974 to develop, manufacture and sell electronic dry cabinets for both industry and home use.

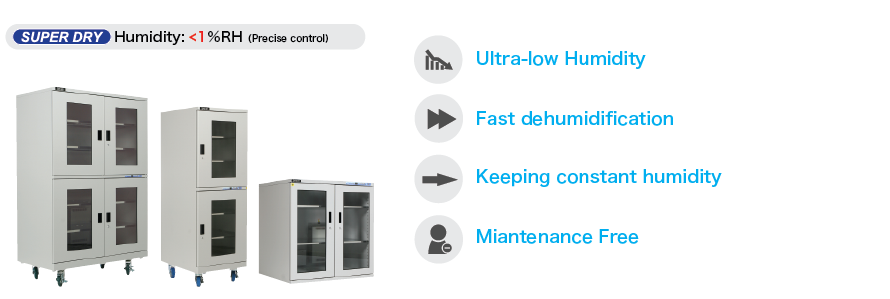

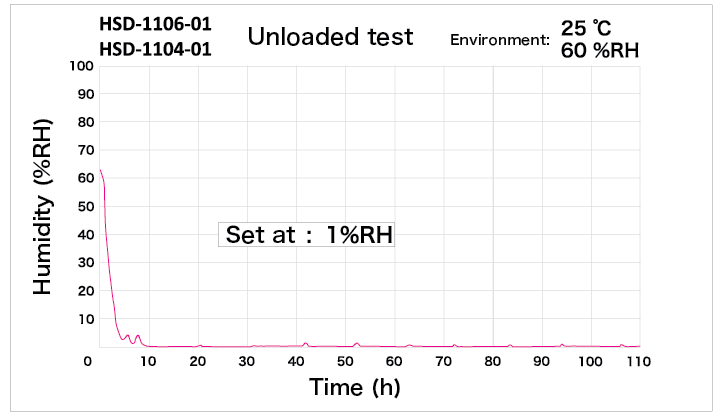

① Advanced technology for ultra low humidity with powerful industrial dry unit installed!

01 series controls min. humidity stable below 1%RH.

02 series controls min. humidity stable below 2%RH.

03 series controls min. humidity stable below 3%RH.

② Super power saving design.

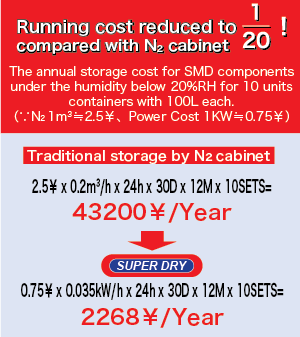

*Running cost reduced to 1/20 compared with N2 cabinet!

③ Superior stability performance, can keep at required humidity for long time.

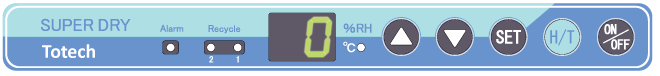

④ Digital control panel

Set the required humidity value precisely from 0~50%RH, Switch display for temperature and humidity, Alarm for excessive humidity, Alarm for door opening, Indicator for recycling.

⑤ Dehumidify with physical process, no need to replace desiccant, can be used with longer duration.

⑥ Customized cabinets are available as per the request for cabinet sizes, inner structure.

Series of SUPER DRY

- M-Temp

- 01-Series

- 02-Series

- 03-Series

- Feeder Series

- HEPA Series

Technologies to realize low humidity

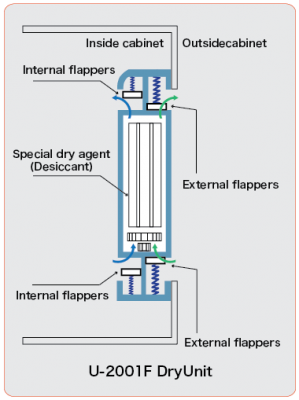

① Dry Agent

High-performance dry agent be able to absorb moisture even if in the humidity below 1%RH.

② Sensor

Capacitance sensor with high accuracy, can monitor the ultra low humidity changes.

③ Electronic dry unit (Convecting and recycling)

Convection helps the air flow to dry unit to accelerate dehumidification. Dry unit recycles and regenerates intelligently with high efficiency.

④ Micro Computer Controlled

Keep ultra low humidity for long time, with high efficiency for regeneration by heating.

⑤ ESD safe requirement: Accords with ESD-IEC61340-5-1 standard.

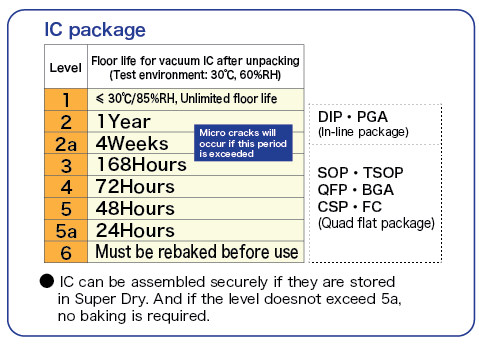

⑥ Low humidity storage for IC: Accords with IPC-JEDEC J-STD-033C standard.

Storage solutions for all kinds of moisture sensitive components

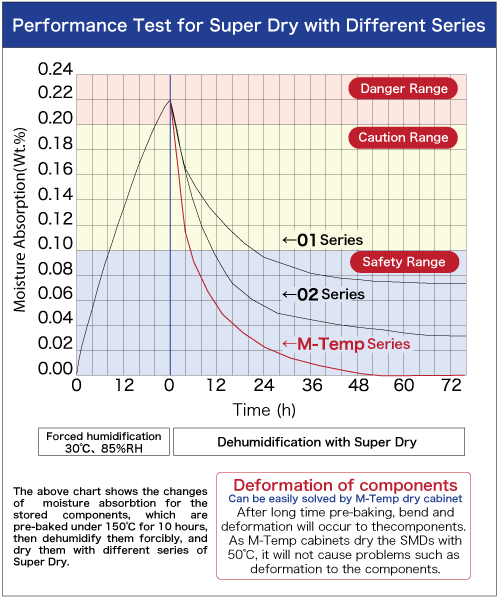

• Measures to avoid cracks on IC package

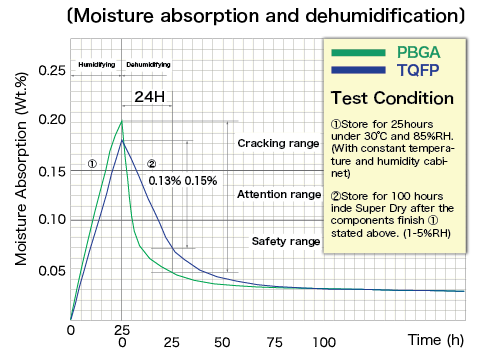

During reflow heating for SMD and IC package, the moisture inside the package will become vapor, causing powder breakage, especially when the weight percentage for moisture inside package is 0.15 for ultrathin IC packages, such as TSOP, TQFP etc., the damage may happen nearly 100%. As a replacement for baking or storage after baking, SUPER DRY is highly recommended.

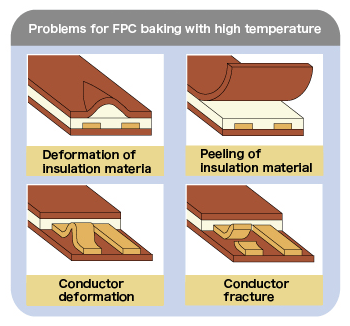

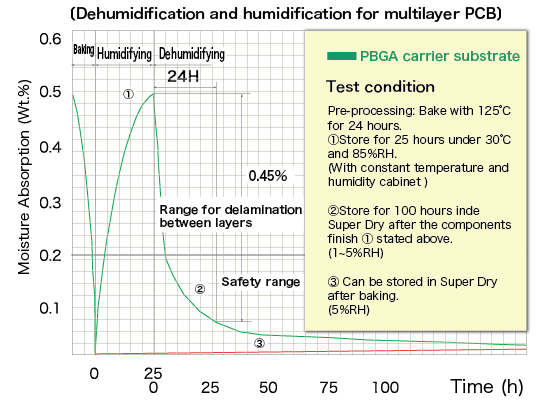

• Storage solution for FPC (Flexiable printed circuit) and multilayered printed circuit board

The moisture absorption is higher if the multilay PCB is thinner, and if the weight percentage exceeds 0.2, reflow heating will cause delamination between layers, so PCBs must be stored inside SUPER DRY.